Automatic 15TPD Waste Plastic/Tyre Pyrolysis To Get Fuel Oil

Plant/Machine/Equipment

Our main products are divided into two catalogries: pyrolysis plant

and distillation machine, including tires pyrolysis plant, tyre

pyrolysis plant, waste rubber pyrolysis equipment, waste plastic

recycling machine

and other waste management machines, and waste oil distillation

equipment, waste engine/motor oil recycling machine, tire oil

distillation plant, plastic oil refinery machine and crude oil

distillation equipment.

Feeding 2 hours —— Pre-heating 2-3 hours —— Oil Producing 8-10hours—— Cooling 3-4 hours —— Carbon black discharging 2 hours —— Steel Pulling 0.5 hour

Workflowchart of waste tire oil pyrolysis plant

First, the raw materials are put into the reactor and seal the

doors in the reactor

Second, start the machine and reactor will rotating and be heated.

When the inside

temperature reaches the degree of 250 to 280, the oil gas will

begin to generate while flow through oilgas separator, and

continuously produce until the temperature up to the degree of 350

to 460.

Third, in oil gas separator, light component will enter the

condensers, meanwhile,

heavy component will be liquefied and then automatically discharged

into heavy oil tank.

Forth, most of the light component will be liquefied through

condensers to crude oil.

Small amount of oil gas cannot be liquefied and will be transferred

by water seal tank back to the burning chamber to be reused as

heating fuel. Carbon black will automatically sent from taphole and

steel wire will pull out.

Technical Specification

| Raw material | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic | Waste rubbers/tyres/plastic |

| Daily Handling capacity | 5 tons | 8 tons | 10 tons | 12 tons |

| Working pressure | Normal pressure | Normal pressure | Normal pressure | Normal pressure |

| Main engine rotating speed | 0.4R /min | 0.4R /min | 0.4R /min | 0.4R /min |

| Power | 15KWH | 15KWH | 15KWH | 15KWH |

| Cooling Mode | Water | Water | Water | Water |

| Floor Area | 200m2 | 250m2 | 300m2 | 300m2 |

| Heating Mode | Direct | Direct | Direct | Direct |

| Oil Yield | 45%-50% | 45%-50% | 45%-50% | 45%-50% |

| Noise dB (A) | <=85 | <=85 | <=85 | <=85 |

| Machine dimension(mm) | D2200*L5000 | D2200*L6600 | D2600*L6600 | D2800*L6600 |

| Working Mode | Intermittence | Intermittence | Intermittence | Intermittence |

Advantages of Batch Waste Tyre Pyrolysis Plant

a) Safety

1) Two devices to avoid backfire in production: oil-water separator

and anti-back fire device.

2) Vacuum device makes reactor working under ordinary pressure or

negative pressure.

3) Temperature monitoring device to avoid excessive working

temperature.

4) Pressure gage to monitor the pressure. If it goes above a

certain level, the bell will alarm and the safety valve will

release the pressure automatically.

5) Carbon black is discharged in a closed situation to avoid

catching fire.

b) Environmental protection

1) The flue gas (caused by burning fuel to heat the reactor) will

be purified and cooled by dust removal device, then can be released

into air through chimney.

2) The procedure to remove carbon black is working under closed

situation to avoid pollution.

c) High oil yield

1) We have 3 steps for cooling system: one condenser pipe, two

large horizontal condensers and two vertical condensers. The oil

gas pass through 3 steps cooling system in sequence. The total

cooling area is 65 square meter.

2) When the oil gas pass through the condensers, it’s divided into

several portions by small pipes inside condenser and be cooled

separately.

3) In this way we maximize the cooling effect and improve the oil

yield.

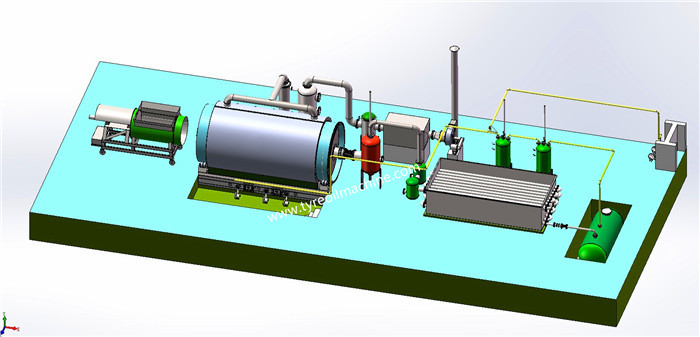

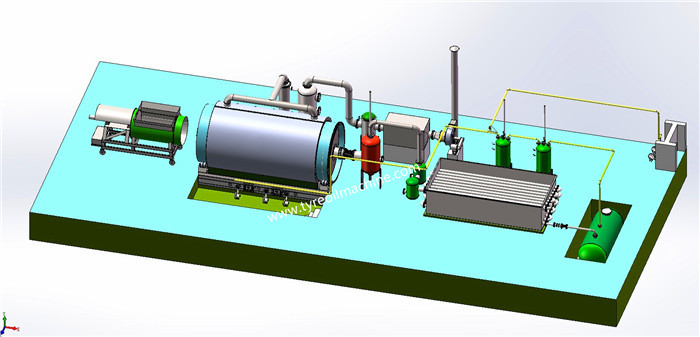

main part for waste tire oil pyrolysis plant

A. horizontal reator

B. oil gas separator

C. vertical condensation system

D. heavy oil tank

E. water seal

F. water tower

G. desulfrization and dedust removal device

H. test pressure and temperature system

I. control panel

J. electricity control system

K. waste gas burning system

L. pipe and others

| | | |

| | | * Sell directly.

* Further refining to get standard diesel and gasoline via

Zhongming distillation machine.

* Use as fuel for heating pyrolysis machine or distillation

machine. |

| | | * Sell directly.

* Further Refine carbon via carbon black refining machine.

* Make pellet via carbon pellet maker. |

| | | * Sell directly.

* Make steel bloom by hydraulic press-packing. |

| | | * Recycle as fuel through gas burner system(we supply gas burner for free).

* Extra gas also can be storage as fuel for other heating. |

Picture Details for tyre pyrolysis machine