12 Ton Full Automatic Tire Pyrolysis Oil Plastic To Oil Recycling

Plant

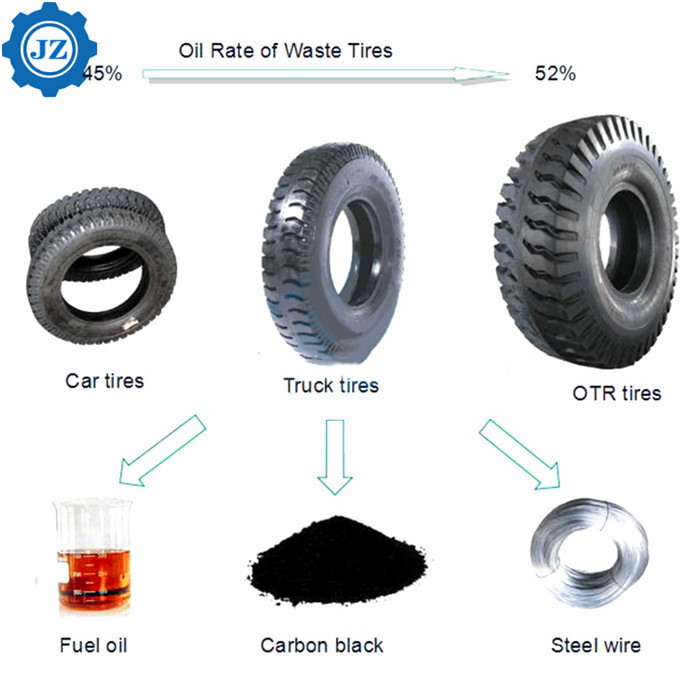

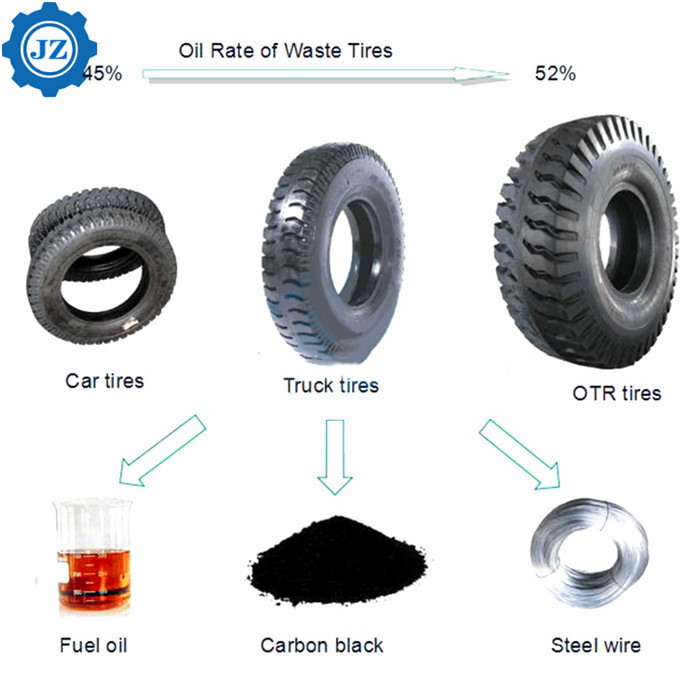

Input raw mateiral

The waste pyrolysis plant can process various kinds of waste

plastic including pp , pe , ps , abs , rubber products ,tires to

fuel oil , carbon black , steel wire.

From waste tire pyrolysis plant, 4 kinds of products can be

obtained: fuel oil, carbon black, steel wire, and incondensable

gas. Fuel oil is widely used in industries, such as steel factory,

heavy oil generator, cement factory, and boiler heating etc. Carbon

black can be made into pellets for making new rubber products.

Steel wire could be sold to the recycle station or steel mill for

remelting. The incondensable gas is recycled to heat the pyrolysis

reactor, saving energy.

Specification

| Tyre Pyrolysis To Fuel Oil Machine |

| 5TPD, 6TPD, 8TPD, 10TPD, 12TPD, 15TPD,50TPD |

| Q345R, Alloy Steel, Stainless Steel |

| 16.45mm, 18.45mm |

| 30-40 tons |

| 15-30KW |

| 2-4 Persons for per set machine, more machine, fewer labors |

| Feeding 2 Hours, Processing 8-9 hours, Carbon Black and Steel Wire

Discharging 1.5 hours. (Take 12TPD capacity as example) |

| Waste Tyre, Waste Rubber, Waste Plastic, Waste Oil Sludge, Waste

Aluminum Foil, Waste Cable, Waste Leather, Waste

Acrylic(PMMA),etc... |

| Pyrolysis Oil, Natural Gas, Electricity, Coal, Firewood, etc... |

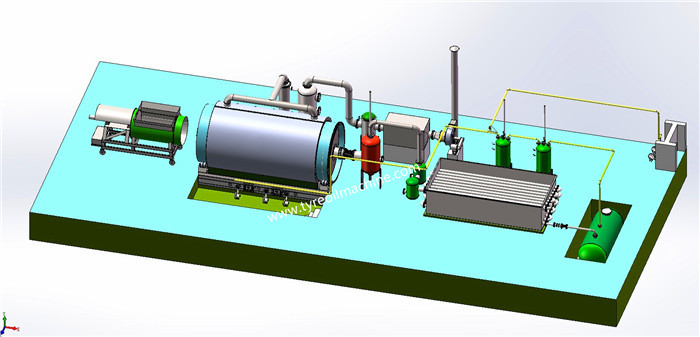

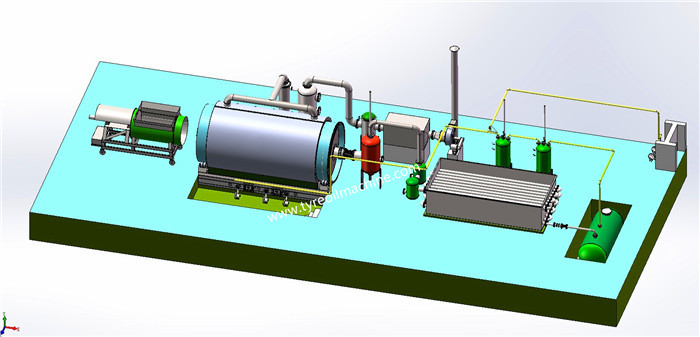

Machine 3D drawing flow chart and working processing

Production Process

Step 1: Feeding (2 hours). Feed tyres into reactor manually or with

auto feeder;

Step 2: Preheating (2-4hours). Tyres gradually melts under high

temperature and oil gas comes out;

Step 3: Oil producing peak (8-10 hours). Oil gas goes through the

cooling system and is cooled down into liquid fuel oil; some oil

gas that cannot be further cooled down into liquid fuel oil under

common temperature and common pressure ("syngas") will be recycled

to furnace for heating, saving your fuel;

Step 4: Cooling (4 hours). After the oil processing process is

completed, leave the plant for cooling.

Step 5: Carbon black discharging (1-2 hours). Use a fully-sealed

carbon black discharging system to discharge carbon black.

Step 6: Pulling out steel wire (0.5h).

advantage and main technical characteristics

| Adopt high pressure and temperature resistance steel plate to

ensure longer service life. For some speical raw material , we use

special steel plate |

High efficiency discharging | Adopt screw converyor discharging device , discharge carbon black

in sealed condition , no pollution and save labour and time . |

Integrated condensing device | All of the condensing parts have been installed together before

delivery from factory , save installation time and ensure welding

quality |

| Auto feeder machine to feed raw material automatically , save

labour and time. |

| All of the motors can be customized.All of the valves use stainless

steel. |

| Adopt 3 layers of ceramic packing dedusting device and water spray

, finally no black smoke discharged out. SGS emission report

provided. |

| Alarm , auto pressure releasing device , and anti back fire device

, vacuum pump to ensure the machine working smoothly. |

Our service

1. Delivery time- It will be 10-15 days after we receive the

deposit.

2. Warranty-The warranty period for reactor and other parts except

spare parts is 1 year.

The problem caused by wrong operation of workers shall not be

responsible by our company.

3. Installation and Training-Our company will send one technician

for each set of machine for guiding your installation, testing the

machine and training your worker.