5Ton 10Ton 15Ton Waste Tire Pyrolysis To Furnace Oil And Carbon

Black Machine

Input raw mateiral

Waste plastic recycling pyrolysis plant is a kind of machine that

can dispose of waste plastic into fuel oil. Plastic to oil ( plastic pyrolysis plant ) is environment friendly

technology for disposal of plastic waste.

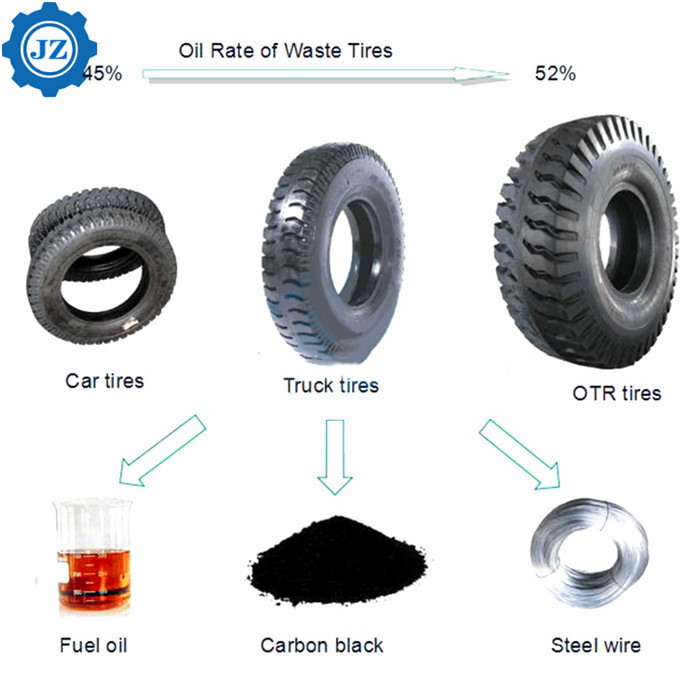

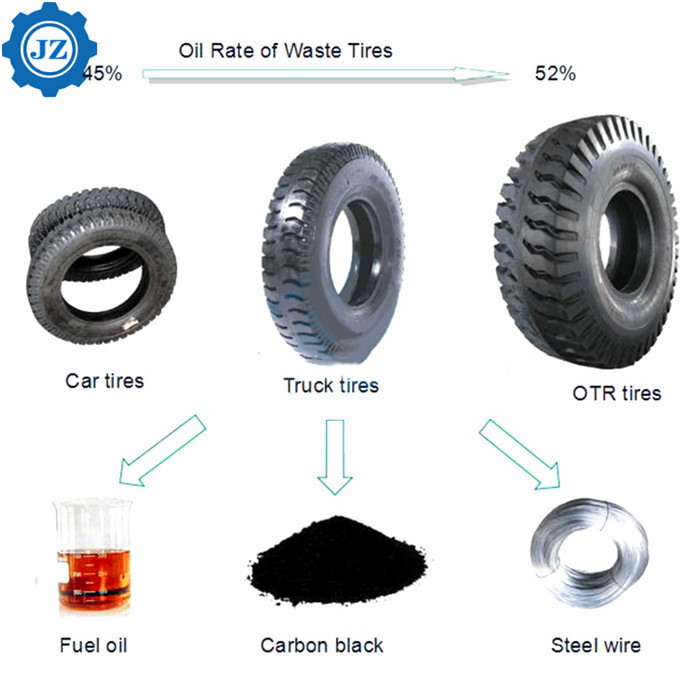

From waste tire pyrolysis plant, 4 kinds of products can be

obtained: fuel oil, carbon black, steel wire, and incondensable

gas. Fuel oil is widely used in industries, such as steel factory,

heavy oil generator, cement factory, and boiler heating etc. Carbon

black can be made into pellets for making new rubber products.

Steel wire could be sold to the recycle station or steel mill for

remelting. The incondensable gas is recycled to heat the pyrolysis

reactor, saving energy.

Specification

| Tyre Pyrolysis To Fuel Oil Machine |

| 5TPD, 6TPD, 8TPD, 10TPD, 12TPD, 15TPD,50TPD |

| Q345R, Alloy Steel, Stainless Steel |

| 16.45mm, 18.45mm |

| 30-40 tons |

| 15-30KW |

| 2-4 Persons for per set machine, more machine, fewer labors |

| Feeding 2 Hours, Processing 8-9 hours, Carbon Black and Steel Wire

Discharging 1.5 hours. (Take 12TPD capacity as example) |

| Waste Tyre, Waste Rubber, Waste Plastic, Waste Oil Sludge, Waste

Aluminum Foil, Waste Cable, Waste Leather, Waste

Acrylic(PMMA),etc... |

| Pyrolysis Oil, Natural Gas, Electricity, Coal, Firewood, etc... |

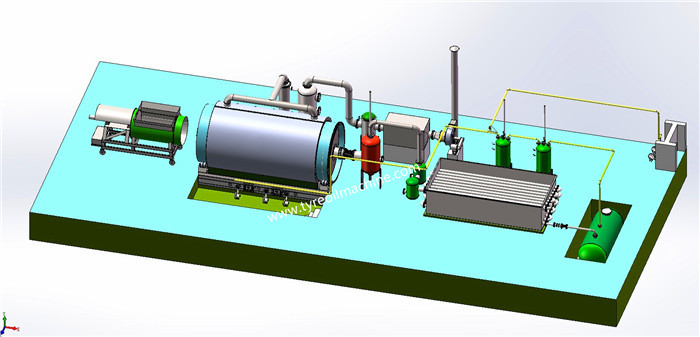

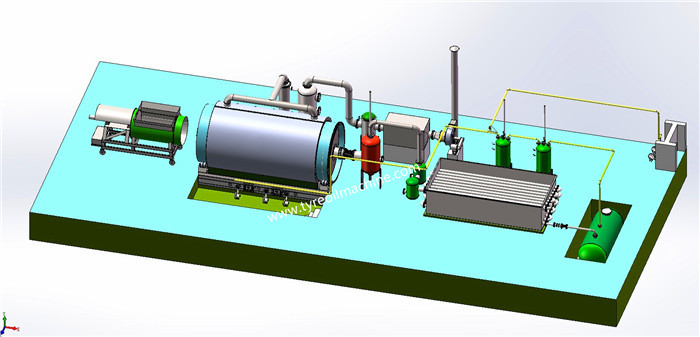

Machine 3D drawing flow chart and working processing

Production Process

1) Feeding: It takes 1-2 hours. Tires below 1.4 meters in the

intermittent cracking system can be fed directly to the whole tire,

and large tires need to be cut before feeding; continuous cracking

systems need to be broken and fed by the feeding system Enter the

host;

2) Heating: It takes about 10 hours. Generally, when it is heated

to 2 hours, oil and gas will be generated;

3) Cooling: Oil and gas are condensed into oil through a cooling

system;

4) Tail gas recovery and utilization: In the process of heating and

cracking, in addition to oil and gas, some flammable but

non-condensable gases are also generated. We call it "tail gas".

This gas can be directly recycled for heating and cracking the

reactor to save Fuel, can also be used to generate electricity or

burn to provide a heat source;

5) Carbon black and steel wire slag removal: When the cracking

process is over and oil and gas are discharged, the remaining

materials in the reactor need to be discharged to carry out a new

cracking process. These residual materials mainly include carbon

black steel wires used to make tires.

advantage and main technical characteristics

1. Safety. We treat safety as the first important thing in

production.

1) Two devices to avoid backfire in production: oil-water separator

and anti-back fire device.

2) Vacuum device makes reactor working under ordinary pressure or

negative pressure.

3) Temperature monitoring device to avoid excessive working

temperature.

4) Pressure gage to monitor the pressure. If it goes above a

certain level, the bell will alarm and the safety valve will

release the pressure automatically.

5) Carbon black is discharged in a closed situation to avoid

catching fire.

2. Environmental protection 10 ton used tire pyrolysis plant

1) The flue gas (caused by burning fuel to heat the reactor) will

be purified and cooled by dust removal device, then can be released

into air through chimney.

2) The procedure to remove carbon black is working under closed

situation to avoid pollution.

3. Energy saving waste tire oil pyrolysis machine

1) The flame path is designed as spiral so that the quantity of

heat can be fully used.

2) The residual gas from pyrolysis is recycled to furnace burning

to heating the reactor.

3) The insulation cover is formed by 3 levels: steel plate, rock

wool and refractory cement. Excellent thermal insulation effect

helps saving fuel.

4. Long service life

1) The material of reactor is Q345R boiler plate with 16/18mm

thickness which is produced by Chinese well-known enterprise. The

head of reactor and accessories are using one-piece molding shell

cover rather than welded plate.

2) All cutting, rolling and welding works are finished by automatic

machines.

3) We know quite well about the material quality and manufacturing

process, that’s why we are confident in the service life of our

products.

4) We also supply installation service, training service and one

year warranty.

Our service

1.Quality warranty period: One year warranty for the main reactor

of pyrolysis machines and lifetime maintenance for complete set of

machines.

2.Our company sends engineers for installation and commissioning in

buyer's site including the training of skills of buyer's workers on

operation, maintenance, etc.

3. Supply layout according to buyer's workshop and land, civil

works information, operation manuals, etc. To the buyer.

4. For the damage caused by the users, our company provides the

parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to

clients.