Fully Automatic Waste Oil Distillation To Diesel Oil Plant With

Solvent Refining Unit

The Latest technology 5-30T waste oil distillation machine to

diesel is amazing technical solution for different

waste oil such as waste engine oil, pyrolysis oil, sludge oil, mud

oil ,very thick dirty impurities oil. This technology is mainly to

use

steam generator to make steam which can have effection with oil gas

to reduce pressure to vacuum level.then when the operation is going

on, diesel can be produced at 300℃ -550℃,however,now the highest

temperature is 300℃ -380℃.in this way oil quality will be highly

improved and also fuel can be used less.

This machine will need one-time catalyst which is produced by our

company only, there is no need to buy from other catalyst factory

as we have the catalyst formula .it is customized.

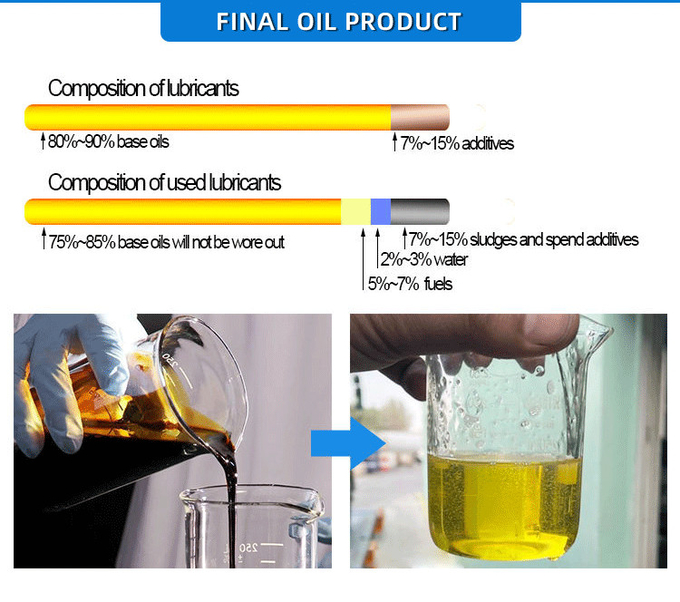

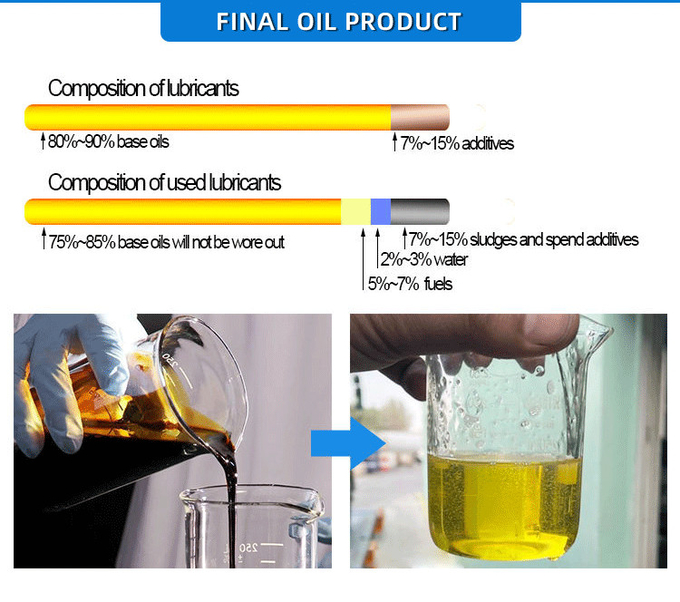

The pyrolysis oil with black color after distillation and remove

color and smell , we will get synthetic diesel oil with yellow

color,which can be used for diesel engines like trucks , tractors ,

ships etc.

| No. | End Production | Yield | Usage |

| 1 | Diesel | 73% | Used for diesel engine |

| 2 | Gasoline | 12% | Used for gasoline engine |

| 3 | Residue Oil | 9% | * Feeding into Pyrolysis Machine for second Pyrolysis

* Sold directly for building road |

| 4 | Non-Condensible Gas | 3% | Recycle as Heating fuel after treated by Gas-treatment System |

| 5 | Other | 3% | * Water and impurity 2%

* Loss 1% |

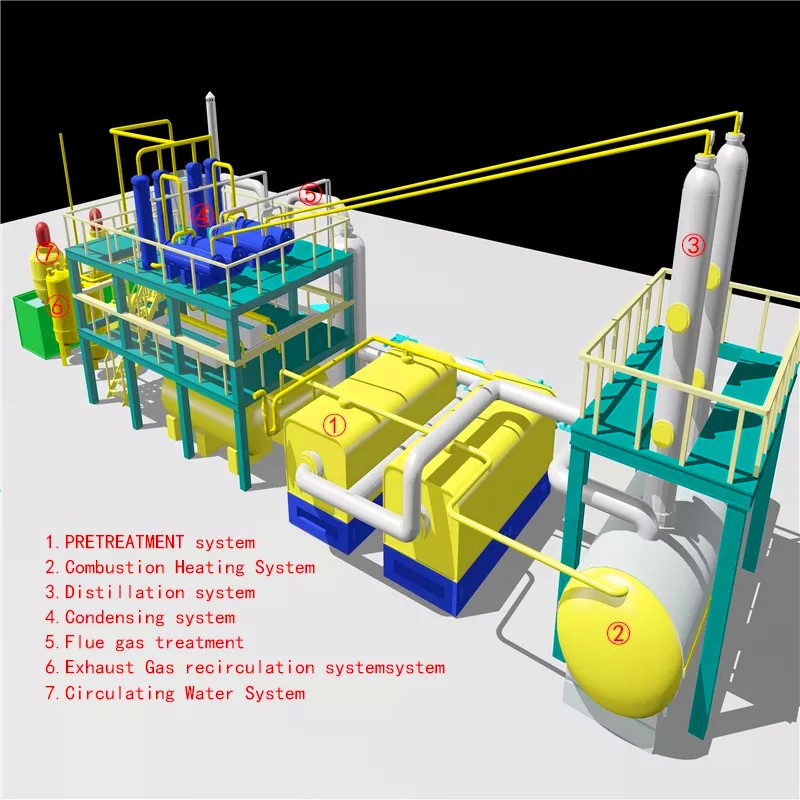

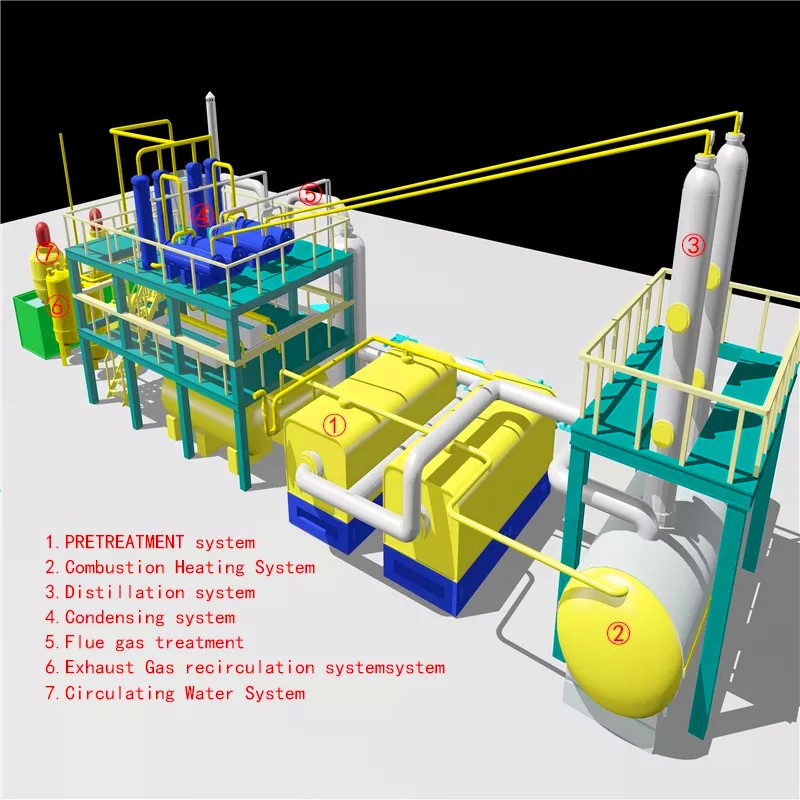

Working process of waste engine oil distillation machine

Negative pressure distillation process

1),Waste engine oil Pre-processing

Settling tank. Put waste engine oil into the settling tank,

separate the water first,then go through the 200 mesh filter to

remove those

impurities such as solid and suspended solid.

2),High temperature flocculation to neutralize the tops

Reboiler. Pump the waste oil that have been pro-processed into the

reboiler,in the condition of vacuum catalyzing and heat-exchanging

to

raise the temperature to 310℃ to 320 ℃

3),Distillation by using vacuum film evaporator

After the temperature raised to 310℃ to 320 ℃ through reboiler,the

oil will be absorbed into the first level taber type film

evaporator

(vacuum degree -0.096--0.098MPa),and can generate a flash

vaporization distillation process,gasifying to distill the light

oil

components,the first level oil come out.

Those pre-processed oil that can not be flash gasified

distillation,will be equably distributed to the upper of vacuum

evaporation surface

in the effort of the evaporator distributor.Then goes to the second

level taper type vacuum film evaporator.When the temperature of

evaporation surface reach 375 ℃--385℃,vacuum

degree(-0.096--0.098),the second level flash evaporation gasifying

process begins.By

gasifying and distilling the light base oil components,the second

level oil come out.

The other oil that failed to be gasified and distilled will go into

the third level taper type vacuum film evaporator.When the

temperature

of evaporation surface reach 430 ℃--450℃,vacuum

degree(-0.096--0.098),the third level flash evaporation gasifying

process begins.By

gasifying and distilling the heavy base oil components,the third

level oil come out.

Those heavy residue oil(asphaltene,colloid) that by no means cannot

be gasified and distilled,in the end will produce a little waste

materials(1%-3%) into the receiver tank,then be discharged.

4),Refining (Distillation sites)

The first level oil ,second level oil,third level oil that come out

through the vacuum film evaporator,will go through the rotating

wire

mesh demister/skimmer(on top of the evaporator),to remove and

purify the heavy residue oil foam drops.Those more purifier oil

goes into

the distillation tower to divide;According to the amount ,the

receiver oil goes into the high temperature vacuum clay adsorption

to

refine.

The after refining base oil will go into their own storage tank

after filtering and cooling down(temperature 50℃--60℃)

SPECIFICATIONS FOR USED ENGING OIL RECYCLING MACHINE |

| 5TPD, 10TPD, 20TPD, 30TPD...300TPD |

| Continuous Working, Semi-Continuous Working |

| Fully Automatic, Semi-Automatic |

| Crude Oil, Used Engine Oil, Waste Hydraulic Oil, Plastic Oil, Tyre

Oil, Mixed Waste Oil, Other waste oil as customer required |

| Fuel Oil, Natural Gas, Electric, Coal, Firewood |

| Q345R Steel Plate, Alloy Steel Plate, Stainless Steel |

| Varies by Design and Capacity |

| Catalytic Pyrolysis Distillation, Refined Filtration, Self-made

Gaseous and Liquid Catalyst,etc... |

Technical Advantage

The equipment adopts advanced vacuum distillation technology, only

need to add a small amount of additive materials which is low cost

and

easy to buy.

The operation cost of the equipment is low, and the high quality

base oil can be produced with very little cost.

The equipment is easy to operate, only 2 workers can operate.

It can process waste oil, waste motor oil, all kinds of waste

engine oil and other mineral lubricating oil.

Its recovery rate is above 85%.

With high vacuum system, to ensure the equipment under the working

vacuum operation.

We have got ISO9001 and ISO14001 Certifications. And also our

products are equipped with CE Certification that

we have the rights to export our waste oil recycling machine to

European. We also have got SGS certificate for

our pyrolysis oil products you can check the oil quality features

from the analysis and chose the right market for

the end products.

we use one 40'FR container to load the reactor, and use the 40'HQ

containers to load the cooling device, dedust

device and some small parts. The reacor is about 9200m

*33400mm*31700mm. It is doable to take 40FR. It is over

width and over height. And Our integrity cooling device is designed

to meet 40HQ size and it is easy to ship and

move the site place.

After-sales service

1.Engineers with over ten years’ waste to oil recycling experience

will be dispatched to your place to provide technical service in

guiding plant installation, plant commissioning as well as worker

training.

2.We all know that good plant design and quality are essential, and

good installation and training service are as important as or even

more important than good plant design and quality. It is very

dangerous if clients can not install or run the plant properly.

3.So, after plant installation finishes, our engineers are required

to help you run the plant for at least 15 batches, enabling your

workers to master all the operating skills needed and then operate

the plant on their own.

FAQ of waste engine oil distillation machine

Q: Are there any bad smell or odor from waste tyre oil distillation

equipment while distillation system is working?

A: There will be no smell at all as the gas produced by waste oil

distillation plant will be purified by our exclusive tail gas

purification unit before emission.

Q: What is the yield of this waste tyre oil distillation equipment?

A: Typically the yield of our waste oil distillation plant is

between 85-90% (depending on variations of water content, light HC

and others ingredients from waste oil.)

Q: How many areas are required to build the waste tyre oil

distillation equipment?

A: The land area required usually depends on the capacity of your

plant. We can calculate the area needed and give you the plant

designs.

Q: What is the warranty of the waste tyre oil distillation

equipment?

A: 12 months free guanantee and life long standard paid service.

Q: Can you install the production line and train our stuffs?

A: Yes we can. We'll send engineers to help you install the waste

oil distillation plant and train your workers until the machine is

skillfully operated.

Successful Case