China Recycling Plant Used Tires Waste Plastic To Oil Pyrolysis

Machine

Pyrolysis Plant is used for recycling waste tire, waste plastic,

waste rubber to fuel oil. According to the actual situation in

every country and district, we developed different models of Batch

Pyrolysis Plants for waste tires, rubber and plastic with daily

capacity 5 -10 tons.

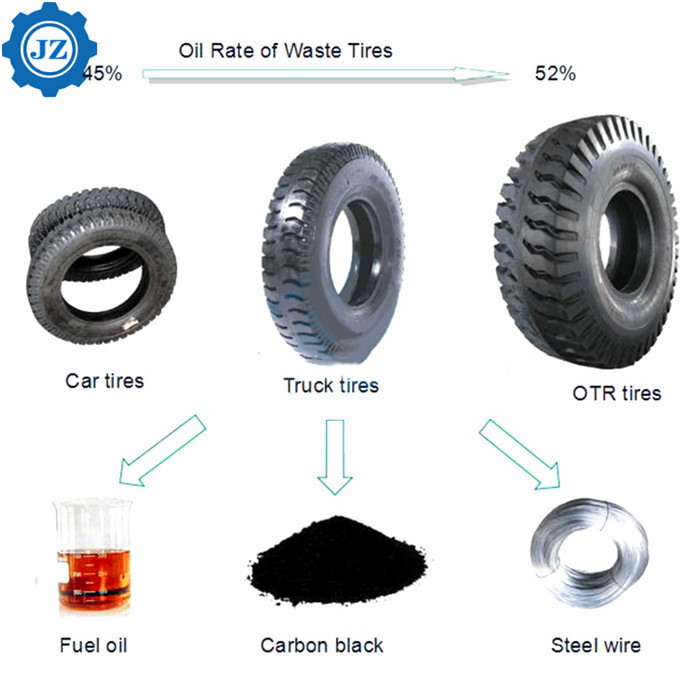

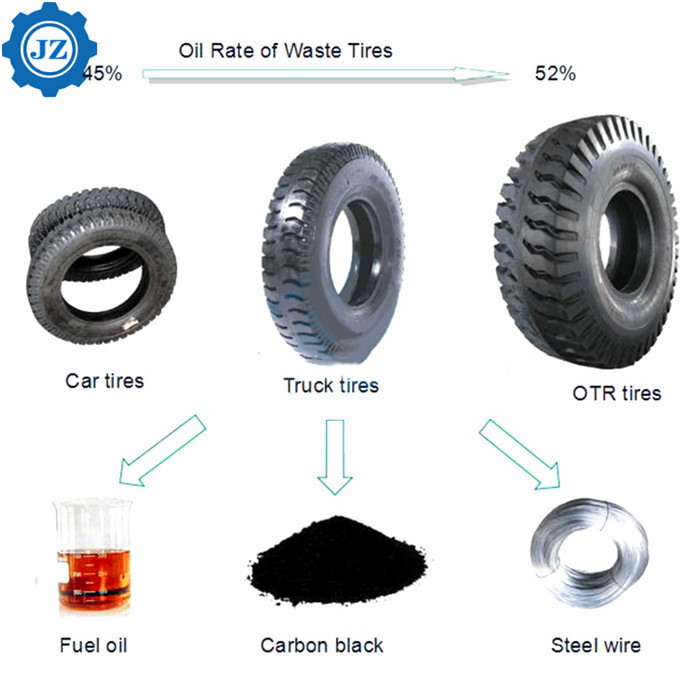

From waste tire pyrolysis plant, 4 kinds of products can be

obtained: fuel oil, carbon black, steel wire, and incondensable

gas. Fuel oil is widely used in industries, such as steel factory,

heavy oil generator, cement factory, and boiler heating etc. Carbon

black can be made into pellets for making new rubber products.

Steel wire could be sold to the recycle station or steel mill for

remelting. The incondensable gas is recycled to heat the pyrolysis

reactor, saving energy.

Specification

| Tyre Pyrolysis To Fuel Oil Machine |

| 5TPD, 6TPD, 8TPD, 10TPD, 12TPD, 15TPD,50TPD |

| Q345R, Alloy Steel, Stainless Steel |

| 16.45mm, 18.45mm |

| 30-40 tons |

| 15-30KW |

| 2-4 Persons for per set machine, more machine, fewer labors |

| Feeding 2 Hours, Processing 8-9 hours, Carbon Black and Steel Wire

Discharging 1.5 hours. (Take 12TPD capacity as example) |

| Waste Tyre, Waste Rubber, Waste Plastic, Waste Oil Sludge, Waste

Aluminum Foil, Waste Cable, Waste Leather, Waste

Acrylic(PMMA),etc... |

| Pyrolysis Oil, Natural Gas, Electricity, Coal, Firewood, etc... |

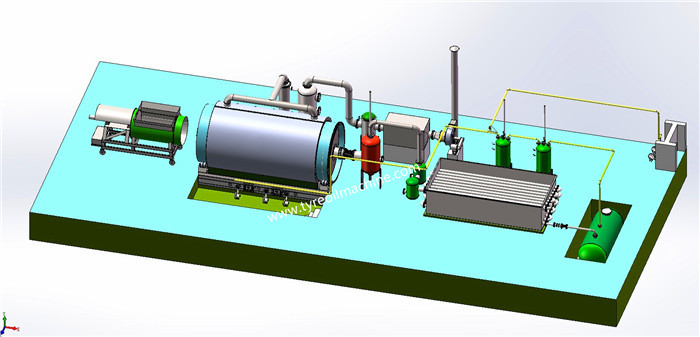

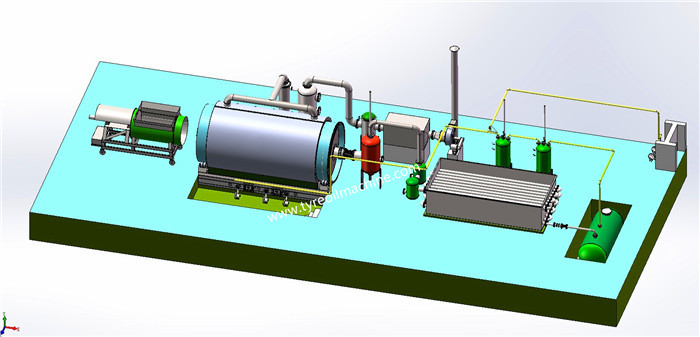

Machine 3D drawing flow chart and working processing

Production Process

Step 1: Feeding (2 hours). Feed tyres into reactor manually or with

auto feeder;

Step 2: Preheating (2-4hours). Tyres gradually melts under high

temperature and oil gas comes out;

Step 3: Oil producing peak (8-10 hours). Oil gas goes through the

cooling system and is cooled down into liquid fuel oil; some oil

gas that cannot be further cooled down into liquid fuel oil under

common temperature and common pressure ("syngas") will be recycled

to furnace for heating, saving your fuel;

Step 4: Cooling (4 hours). After the oil processing process is

completed, leave the plant for cooling.

Step 5: Carbon black discharging (1-2 hours). Use a fully-sealed

carbon black discharging system to discharge carbon black.

Step 6: Pulling out steel wire (0.5h).

Technical Parameter of Waste Tyre Pyrolysis Plant

| NO. | ITEM | PROJECT |

| 1 | Equipment Model | JZ-5 | JZ-10 |

| 2 | Door Model | Full Open Door/Oval Open Door | Full Open Door/Oval Open Door |

| 3 | Suitable Raw Materials | Tyre/Rubber | Tyre/Rubber |

| 4 | Structure | Horizontal Type Revolves | Horizontal Type Revolves |

| 5 | Reactor Size | Φ2200*6000mm | Φ2600*6600mm |

| 6 | Capacity for One Batch | 3ton, 5ton | 10ton, 12ton, |

| 7 | Oil Yield of Tires | 40%-45% | 40%-45% |

| 8 | Work Pressure | Normal Pressure | Normal Pressure |

| 9 | Reactor Rotation Speed | 0.4R/M | 0.4R/M |

| 10 | Fuels Choice | Coal, Wood | Coal, Wood, Gas, Oil |

| 11 | Power | 18KW/H | 25KW/H |

| 12 | Cooling Method | Water Cycling | Water Cycling |

| 13 | Type of Drive | External Annular Gear | External Annular Gear |

| 14 | Heating Method | Direct | Direct |

| 15 | Type of Installation | With Foundation | With Foundation /Integrated Base |

| 16 | Noise dB(A) | ≦85 | ≦85 |

| 17 | Operation Mode | Intermittent Operation | Intermittent Operation |

| 18 | Total Weight(MT) | 25 | 40 |

| 19 | Installation Space Required | 30m*10m | 30m*10m |

| 20 | Manpower | 2~3/batch | 3~4/batch |

| 21 | Shipment | Ф2200×6000=1*40HC+1*40FR | Ф2200×6000=1*40HC+1*40FR |

Main advantage and technical characteristics

1. Oval door or Full open door: Domestic patent, convenient and fast to load materials, fast

cooling, and it is convenient and rapid to produce steel wire;

2. Thorough cooling effect of condensers, high oil yield, good oil

quality, long service life, easy to clean;

3. Water membrane type desulfurization and de-dusting: National patent, can effectively remove acid gases and dust and

reach related national standards;

4. Large furnace door, deslagging in center: High temperature, closed, automatic slag-out, clean, dust-free,

rapid and time-saving;

5. Safety: Automatic submerged arc welding technology, ultrasonic

nondestructive testing, manual and automatic safety device;

6. Exhaust gas recovery system: Fully burned after recovery, save fuel and prevent pollution;

7. Direct heating: Increase the heating area of the furnace, heating up fast, easy to

control the temperature, and effectively extend the service life of

equipment;

8. Insulation shell design: National patent, excellent insulation effect and good

energy-saving effect.

Our service

1.Quality warranty period: One year warranty for the main reactor

of pyrolysis machines and lifetime maintenance for complete set of

machines.

2.Our company sends engineers for installation and commissioning in

buyer's site including the training of skills of buyer's workers on

operation, maintenance, etc.

3. Supply layout according to buyer's workshop and land, civil

works information, operation manuals, etc. To the buyer.

4. For the damage caused by the users, our company provides the

parts and accessories with cost price.

5. Our factory supplies the wearing parts with the cost price to

clients.

Successful Case