85% Oil Rate Waste Engine Oil Recycle To Diesel Distillation

Refining Plant

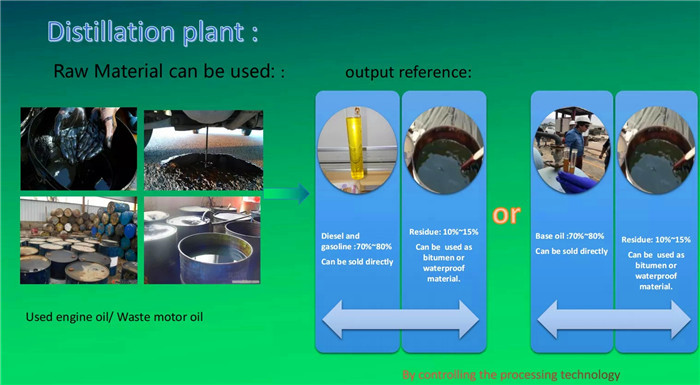

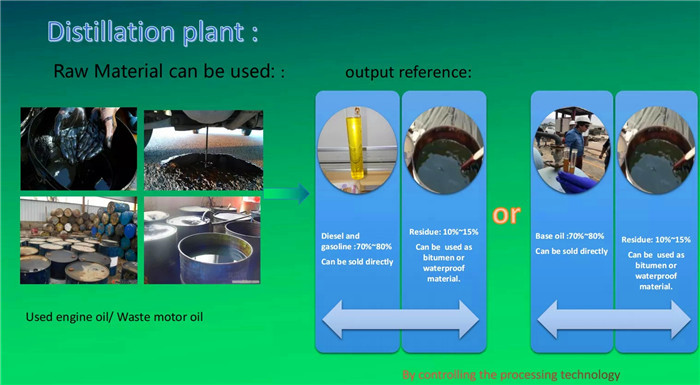

With the distillation machine can recycle waste tire pyrolysis oil,

waste plastic pyrolysis oil, waste engine oil, waste lubricant oil

and oil sludge into diesel.

Input capacity: 5ton-30ton

Output capacity per day: 3ton-10ton

Fuel for heating: coal / wood / natural gas / distillate oil

Installation cover area: 300-400 square meters

Workers: need 2-3 workers for machine operation

This Waste Engine Oil Distillation Machine will need one-time

catalyst which is produced by our company only, there is no need to

buy from other catalyst factory as we have the catalyst formula .it

is customized.

The pyrolysis oil with black color after distillation and remove

color and smell , we will get synthetic diesel oil with yellow

color,which can be used for diesel engines like trucks , tractors ,

ships etc.

| No. | End Production | Yield | Usage |

| 1 | Diesel | 73% | Used for diesel engine |

| 2 | Gasoline | 12% | Used for gasoline engine |

| 3 | Residue Oil | 9% | * Feeding into Pyrolysis Machine for second Pyrolysis

* Sold directly for building road |

| 4 | Non-Condensible Gas | 3% | Recycle as Heating fuel after treated by Gas-treatment System |

| 5 | Other | 3% | * Water and impurity 2%

* Loss 1% |

Technical Specification

| Waste Oil To Diesel Distillation Machine |

| 5TPD, 10TPD, 20TPD, 50TPD,100TPD,300TPD |

| Q345R, Alloy Steel, Stainless Steel |

| 16.45mm, 18.45mm |

| 80-300 tons (Varies by Design and Capacity) |

| 45-450KW(Varies by Design and Capacity) |

| 4-15 Persons for per set machine, more machine, fewer labors |

| Feeding Raw Material, Heating and Reacting, Sludge Oil Discharging |

| Fuel Oil, Used Engine Oil, Heavy Oil, Tower Bottom Residue Oil,

Waste Tyre Oil, Waste Hydraulic Oil,Crude Oil, Waste Plastic Oil,

etc... |

| Pyrolysis Oil, Natural Gas, Electricity, Coal, Firewood, etc... |

Working process of waste engine oil distillation machine

Distillation plant works as follows:

1. Pump waste oil into distillation reactor by oil pump.

2. Heat the reactor, and the liquid oil will slowly become oil gas,

oil gas will go through catalytic chamber and condenser,

then diesel will be cooled out first by controlling the temperature

over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150

Celsius degrees, the rest of the system is same as pyrolysis

system.

The main list of waste oil distillation equipment

A. Vertical reactor/Horizontal reactor

B. Reducer system

C. Condensation system

D. Collector

E. Oil collecting tank

F. Residue tank

G. Oil-gas separator

H. Water cooling system

I. Water seal

J. Pressure & Temperature monitoring gauge

K. Deodorization system

L. Efficient anti clog cooling system

M. Gas heating system (waste gas process system)

N. Smoke desulphurization and dust removal system

Advantage of used engine oil to diesel recycling distillation plant

Safety

Safety is the most important factor in the whole process. We had

successfully researched some safety devices which ensure used

engine oil to diesel recycling distillation plant work safely.

1. Safety valves, alarming device and the pressure gauge etc.

2. We also have oil-water separator which can stop the oil gas

recycle to the reactor, which could avoid the accident.

3. High degree of automation: feed the waste oil, crude oil

automatically, to pump oil automatically.

Energy saving

1. Well sealing for heating system, no gas leak and saving fuel.

2. Continuous feeding with automatic feeder, no gas leak.

3. Recycling of exhaust gas and scientific fire channel design can

save energy and thereby reducing costs.

Environmental friendly

1. The whole process is all sealed, won't release any gas harmful

to human and environment.

2. Well water dedusting system can avoid black smoke.

After-sales service

1.Engineers with over ten years’ waste to oil recycling experience

will be dispatched to your place to provide technical service in

guiding plant installation, plant commissioning as well as worker

training.

2.We all know that good plant design and quality are essential, and

good installation and training service are as important as or even

more important than good plant design and quality. It is very

dangerous if clients can not install or run the plant properly.

3.So, after plant installation finishes, our engineers are required

to help you run the plant for at least 15 batches, enabling your

workers to master all the operating skills needed and then operate

the plant on their own.

FAQ of waste engine oil distillation machine

1. Who has run the waste tire/plastic to oil recycling pyrolysis

machines?

A: The waste tire/plastic to fuel recycling pyrolysis machines have

been installed in 25 countries all over the world.

2. What can I get from the machines?

A: From 10T pyrolysis machine, you can get 4-5T tire oil or 2T-7.5T

plastic oil, 2.5-3T carbon black, 1.5-2T steel wire, 5%-10% syngas.

3. How much profit do I get from the pyrolysis machine? What's in

it for me?

A: This machine can get you hundreds to over 1,000USD profit gross

profit per day.

The accurate profit varies with your local raw material cost,

amount and your output selling price. If you provide these prices,

we can give you a specific profit analysis report.

By the way, the more tyre/plastic you process per day, the lower

the average management cost and the more profit you get.

4. What matter most to this waste tire/plastic to oil recycling

pyrolysis business?

A: Safety. It's the most important thing in this high-profit oil

gas business.

Environment friendly

Energy-saving

Installation&worker training

Technical support&update

Service

Successful Case