30ton Continuous Waste Plastic Scrap Tyre Recycling Pyrolysis To

Oil Plant

Scrap Tyre Pyrolysis To Fuel Oil Machine

Capacity:20TPD,30TPD,50TPD

Reactor Material:Q345R, Alloy Steel, Stainless Steel

Reactor Thickness:16mm, 18mm

Total Weight:30-40 tons (Varies by Design and Capacity)

Working Power:15-60KW(Varies by Design and Capacity)

Labor Qty Require:2-4 Persons for per set machine, more machine,

fewer labors

The waste tire pyrolysis plant is decomposed into oil vapor by high

temperature pyrolysis technology, and the oil vapor enters the

cooling system through the oil gas separator, wherein the oil flows

to the oil tank, and the pyrolysis gas passes through water seal to

the gas recovery system to become the main furnace fuel. Realize

continuous production.

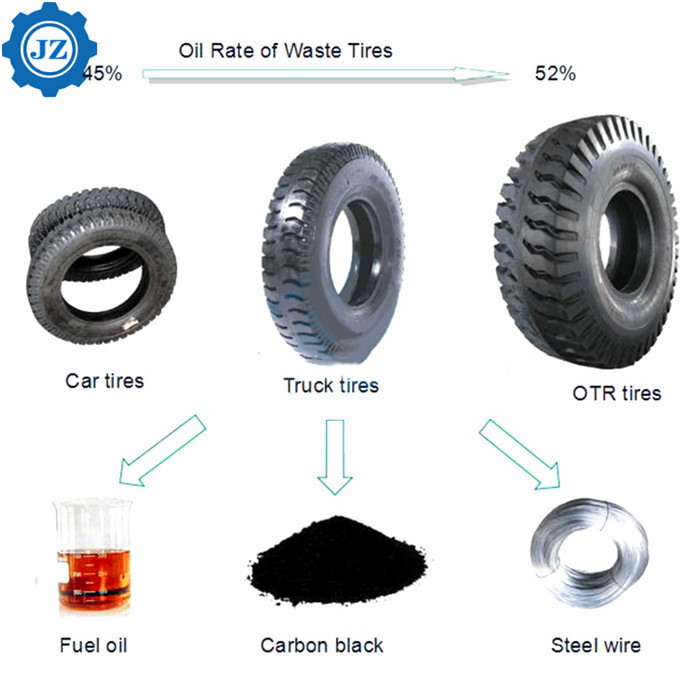

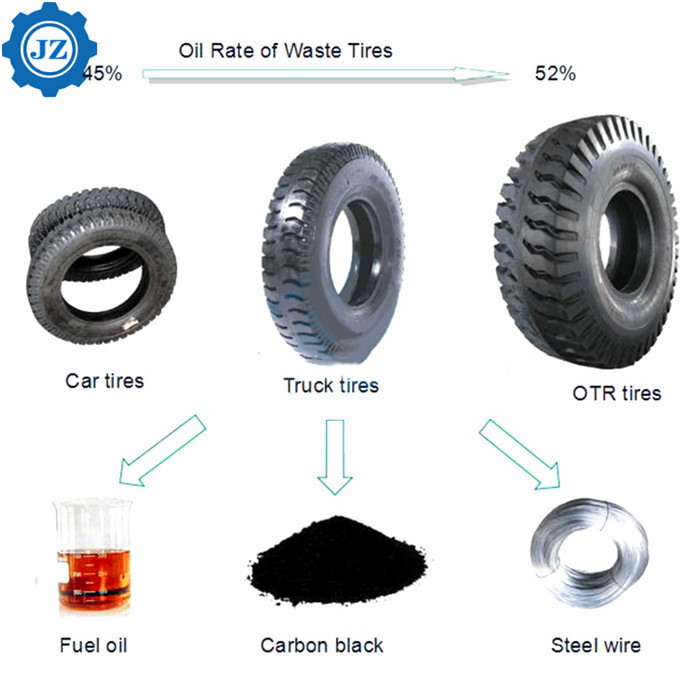

. | Raw material | Note |

1 | Waste tyre | Steel tyre,Nylon tyre ,Bick tyre |

2 | Waste plastic | PE,PVC,Waste washed mixture plastic from waste Paper Factory |

3 | Waste rubber | Shoes Soles,Cable Skin |

4 | oil sludge,waste oil sludge | Tank bottom sludge,oil spill on ground |

Technical Specification

| Item | Contents |

| Input-Raw Materials | Waste tire/rubber/Medical waste/MSW |

| By-products | Fuel oil, carbon black, steel wire, syngas |

| Model | Reactor size | Capacity |

| 2200*5500 | 5 Ton/Batch |

| 2200*7500 | 7 Ton/Batch |

| 2600*6600 | 8 Ton/Batch |

| 2800*6000 | 9 Ton/Batch |

| 2800*6600 | 10 Ton/Batch |

| Reactor material | Q345R/Q245R/310S+Boiler plate/Stainless steel |

| Thickness | 14mm/16mm/18mm |

| Weight | 15T-35T |

| Power | Average 15KW/h |

| Space needed | 300-400 square meters (Width:10m, Length:30m-40m) |

| Labor needed | 3-4 workers |

| Density of oil | 0.89g/cm3 |

| Combustion value | 44.30KJ/KG |

| Note: | We supply customized mini plant: 10kg plant, 1ton plant for

customer trial operation. |

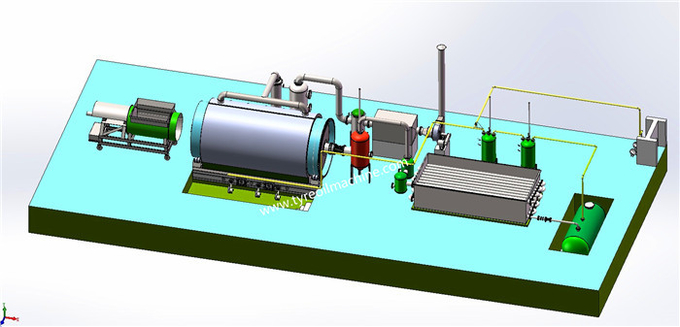

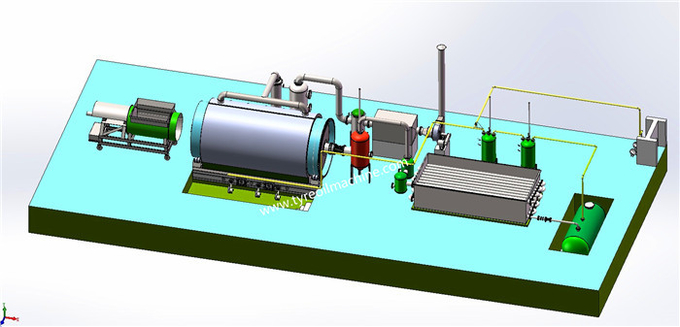

Main Working Process of scrap tire pyrolysis plant

1. Put raw materials into reactor by auto-feeder, then heat the

reactor. Do not stop heating the reactor, when the temperature

reaches nearly 250 degree Celsius, waste tyre will be transferred

to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then

collected by oil tank.

3. The exhaust gas which can not be cooled in normal pressure will

be recycled to heat the reactor. Smoke produced by processing the

tyres can achieve national emission standard through dual

desulfurization and dusting removal device.

4. After you get oil,the temperature will be low, at this time,

carbon black will be discharged automatically.

Technical Advantage

1. Safety

The waste tyre pyrolysis machine business is equipped with mature

safety devices, such as alarm for over temperature and pressure,

auto pressure releasing system, extra gas recycling system and fire

fighting device, which will guarantee 100% safety in the tyre to

oil recycling process.

2. Energy-saving

By the extra gas recycling system, the gas that can not be

condensed will be recycled to the burning room. It can replace the

fuel material to heat the reactor, which will reduce additional

fuel consumption.

3. Environment friendly

In the dedusting system, three steps (water spray, ceramic ring

filter, washing chamber) are used to dedust the extra gas and more

than 95% of the dust would be removed. The released gas is

pollution-free and can be discharged into the air directly with

ISO9001:2008,CE Certificate.

4.Strict requirements for quality

IQC:Incoming quality control,main raw material;

PQC:Process quality control,All the reactor is inspection by X-ray.

Main technical characteristics

Auto-feeder(optional device)

1. 50 ton hydraulic pressure help feeding more raw materials.

2. The diameter is 1.4m. It can feed all kinds of raw materials,

including plastic, packages of plastic, truck tire, car tire, or

tire pieces after cutting.

3. Save labor, save time.

4. After finishing production it can feed raw material instead of

waiting the main furnace to be cooled.

Oil separator

1. Water from raw material will be separated here.

2. Water sealing design prevent tempering. Ensure saftety.

3. Heavy oil will be collected here.

Cooling system

1. Coil pipe cooling system

there are 24 Ø159 pipes lied in the water pond,each pipe 6 meters

long, oil gas can be cooled in larger area and longer time,thus get

higher oil yield

2. Vertical condensers

we supply 4 condensers, each has 44 pipes inside the condenser.

Saves space and looks more neat and beautiful.

Anti-back fire device

1. Little residual gas can not be cooled. It will recycle these gas

to furnace burned to heat the main furnace .

2. Water sealing disign will prevent tempering. Ensure safety.

Double dust removal device

1. Dispose of flue gas caused by heating main furnace using coal,

wood, oil or natual gas.

2. Environment protection.

Installation Project