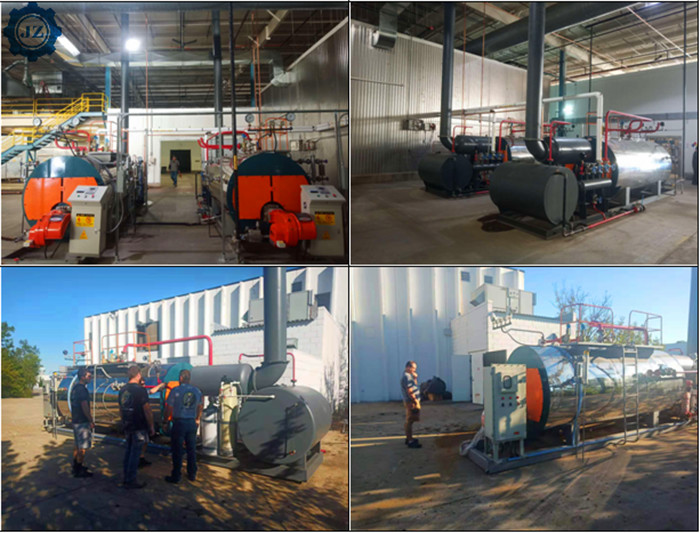

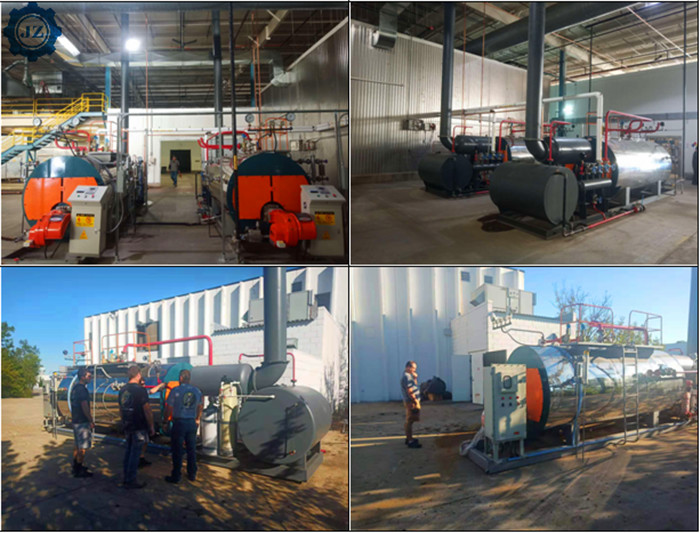

High Efficiency Industrial Diesel Fired Steam Boiler For Mushroom

Cultivation

Model: WNS Series Oil Gas Steam Boiler

Structure:Wet Back Fire Tube Packaged steam boiler

Fuel:oil, gas, light oil, heavy oil, natural gas, lpg, lng, cng,

diesel, biogas etc

Capacity:1-20 ton per hour

Pressure:0.7/1.0/1.25/1.6 Mpa (7/10/12.5/16 Bar)

Temperature:170/184/194/204 Celsius

Application:Chemical, food and brewery, pharmaceutical, package

plant, textile dyeing and printing industry, swimming pool,

hospital,school,clothing industry etc.

WNS type automatic horizontal steam boiler is a horizontal quick -

mounted internal - burning three - return - trip fire tube

boiler.The bifurcated flue gas is used to wash the second and third

return flue gas pipes successively, and then the flue gas chamber

is discharged into the atmosphere through the chimney.The boiler is

fitted with movable front and rear smoke box covers to facilitate

boiler maintenance.

Steam Boiler Specification

| model | WNS0.5-1.0-Y(Q) | WNS0.7-1.0-Y(Q) | WNS1-1.25-Y(Q) | WNS1.5-1.25-Y(Q) |

| Steam Capacity | 500 KG/H | 700 KG/H | 1000 KG/H | 1500 KG/H |

| Boiler Horsepower | 30 HP | 50 HP | 70 HP | 100 HP |

| Working Pressure | 0-10 BAR | 0-10 BAR | 0-13 BAR | 0-13 BAR |

| Steam Temperature | ≤184 ℃ | ≤184 ℃ | ≤194 ℃ | ≤194 ℃ |

| Fuel Type | Gas, Oil | Gas, Oil | Gas, Oil | Gas, Oil |

Performance Features:

1. Steam boiler

Horizontal internal combustion three return journey full wet back

design, corrugated furnace, with good thermal retrability, water

cooled retrorse chamber, retrorse chamber and back tube plate

butted on the edge, low stress, more reliable quality.

2, large diameter corrugated furnace

The boiler combustion chamber is composed of a large diameter full

ripple furnace with large combustion space, complete fuel

combustion, effective heat absorption and thermal expansion, and

large radiation heating surface.

3. Sufficient heat

The heating area of the boiler is designed to be more than 25

square meters/ton, fully absorbing effective heat, low smoke

exhaust temperature, small heat loss, ensuring sufficient output

and high efficiency.

4. Steam quality

Pot shell diameter, large water capacity, strong adaptability to

load changes, stable output, steam space volume, soda interface and

steam outlet net distance is high, low steam humidity.

5. Multi-functional safety and explosion protection device

The back plate of the boiler is equipped with the explosion-proof

device which is connected with the furnace to prevent the high

energy of the discharge moment when the fuel is violently deflated

in the furnace, and it can automatically reset. Meanwhile, it has

the function of the fire-viewing mirror and the maintenance

channel. It makes use of the adjustment of the burning flame in

operation, and makes the furnace inspection and maintenance

convenient.

6. Safe precipitation time is sufficient

The position of the boiler combustion chamber is arranged, the

water level is determined in accordance with the regulations, and

the water level fluctuation time requirements strictly in

accordance with the international general norms and standards, with

sufficient safe precipitation space, to ensure the operation safety

of the boiler.

7. Boiler maintenance is convenient

The top of the boiler is provided with manhole, and the front and

rear of the boiler is provided with hand hole device, which is

convenient for inspecting and cleaning the device inside the boiler

and the bottom of the boiler.

8. Unique seal of front and rear smoke box

Smoke box with double open door, easy to open, multi-level

labyrinth seal, special sealing material, good compression

performance, completely prevent smoke leakage, can be used again.

9. Reliable protection of pressure and water level

Multiple control protection for boiler pressure and water level, as

well as ultra-smoky temperature protection ensure the safety of

boiler operation.

10. Advanced automatic control

The boiler controller is made of Siemens and Delixi electric

components with reliable performance.Chinese and English menu with

LCD display, touch screen with remote control.

Gas/oil fired steam boiler is widely used in hospitals, schools,

textile mills, garment factories, large supermarket, garment

factories, dyeing factory, hotel, dining room, restaurant, food

factory, beverage factory, soy products, meat products factory,

cannery, brewery, pharmaceutical factory, packaging plant, building

materials factory, paint factory, swimming pool and other places of

the enterprises and institutions.

After Sale Service

1. 100% safety, running stably, excellent water level and pressure

control, fully automatic operation. Adopt multi-level interlocking

protection.

2.Boiler running life > 20 years.

3. Good after-sale service. It is free for you to get the damaged

spares in warranty period (1 year) if there is any questions.

Assure that we can supply you spares in boiler’s all life.

4. Use special paint after assembly. Paint is especially suitable

for your climate area, with corrosion resistance, wear resistance

and color fastness.

5. If you have any problems during the installation and use, please

feel free to contact us. We will contact you at the first time to

solve the problems. We have many after-sales service centers, as

well as efficient multilingual, telephone, video services and

professional and reliable remote services.

6.Comprehensive after-sales service. We can design layout drawings

of boiler system according to your actual requirement. Also can

arrange engineers to guide installation & commissioning.