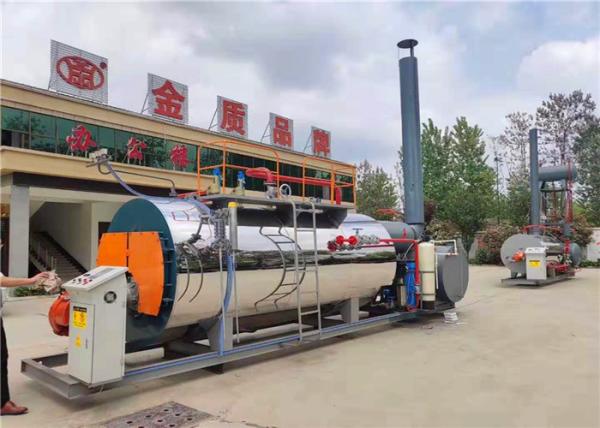

Low Pressure Plc Control Lpg Or Natural Gas Fired Steam Boiler For

Food And Brewery

Model: industrial gas oil fired steam boiler

Structure:horizontal fire tube, wet back, three pass

Steam Capacity:1-20ton/hour

Steam

Pressure:1.0Mpa(10bar),1.25Mpa(13bar),1.6Mpa(16bar),2.5Mpa(25bar)

Steam Temperature:184 °c,194°c, 204°c,226°c(As long as the steam

temperature you need is lower than 226°c, we can do it).

Fuel:heavy oil, light oil, natural gas, city gas, lpg,lng,etc

Application: textile mill, food, beer and brewery factory,chemical

industry, garment factory, printing mill, paper masking

industry,milk pasteurization, pharmaceutical industry etc.

WNS series oil and gas steam boiler adopts shell type full wet back

type fire tube structure. The structure adopts three return

journeys, in which the oil or gas is well atomized by the burner

and fully mixed with the air, and is completely burned in the

corrugated furnace bile, and then turns from the rear smoke chamber

into the return smoke pipe, turns to the front smoke box into the

return smoke pipe, enters the back smoke box, and is discharged by

the chimney.The size of the furnace liner we choose is large, which

provides conditions for the full combustion of fuel, so this

packaged steam boiler can burn heavy oil, light oil, natural gas

and city gas. In addition, our company adopts threaded smoke pipe

in the design, and the relative flow rate can control low smoke

resistance, low power consumption and large load regulation ratio

under the guarantee of sufficient heat transfer.

Performance Features:

1. Steam boiler

Horizontal internal combustion three return journey full wet back

design, corrugated furnace, with good thermal retrability, water

cooled retrorse chamber, retrorse chamber and back tube plate

butted on the edge, low stress, more reliable quality.

2, large diameter corrugated furnace

The boiler combustion chamber is composed of a large diameter full

ripple furnace with large combustion space, complete fuel

combustion, effective heat absorption and thermal expansion, and

large radiation heating surface.

3. Sufficient heat

The heating area of the boiler is designed to be more than 25

square meters/ton, fully absorbing effective heat, low smoke

exhaust temperature, small heat loss, ensuring sufficient output

and high efficiency.

4. Steam quality

Pot shell diameter, large water capacity, strong adaptability to

load changes, stable output, steam space volume, soda interface and

steam outlet net distance is high, low steam humidity.

5. Multi-functional safety and explosion protection device

The back plate of the boiler is equipped with the explosion-proof

device which is connected with the furnace to prevent the high

energy of the discharge moment when the fuel is violently deflated

in the furnace, and it can automatically reset. Meanwhile, it has

the function of the fire-viewing mirror and the maintenance

channel. It makes use of the adjustment of the burning flame in

operation, and makes the furnace inspection and maintenance

convenient.

Technical Parameter

| Model | Rated | Rated | Rated | Thermal | Fuel Consumption | Equipment Power | Weight |

Capacity (t/h) | Pressure (Mpa) | Temperature (C) | Efficiency (%) | Light oil (Kg/h) | Natural gas (Nm³/h) | Burn light oil | Burn gas | (t) |

| WNS1 | 1 | 0.7/1.0/1.25 | 170/184/194 | >90 | 45-100 | 18-100 | 1.5 | 1.5 | 4 |

| WNS1.5 | 1.5 | >90.2 | 101.73 | 123.47 | 2.2 | 1.5 | 5 |

| WNS2 | 2 | 1.0/1.25/1.6 | 184/194/204 | >90.2 | 137.09 | 165.97 | 2.2 | 3 | 8 |

| WNS3 | 3 | >91 | 205.75 | 249.6 | 7.5 | 7.5 | 9 |

| WNS4 | 4 | >91 | 272.3 | 329.5 | 9 | 7.5 | 13 |

| WNS5 | 5 | >91.5 | 134-402 | 80-500 | 17.2 | 15 | 15 |

| WNS6 | 6 | >91.5 | 134-402 | 80-500 | 15 | 15 | 17 |

| WN8 | 8 | 1.25/1.6/2.5 | 194/204/225 | >91.6 | 523.4 | 631.5 | 26 | 22 | 21 |

| WNS10 | 10 | >91.6 | 212-890 | 150-1085 | 26 | 22 | 22 |

| WNS12 | 12 | >91.8 | 915.5 | 1090 | 26 | 22 | 27 |

| WNS15 | 15 | >91.8 | 931.5 | 1094.4 | / | / | 34 |

| WNS20 | 20 | >92 | 1380.33 | 1598.44 | / | / | 45 |

| Note: Parameter is for reference only, we can design the boilers

based on customers’ needs. |

Excellent Structure

Free-Assembly

Portable System

Three Fire-Passes

New Wet-Back Design

Corrugated Furnace, Fire-tube

Safety Technologies

Automatic Ignition

Automatic Water-Level Control

Automatic Over-Pressure Relief

Automatic Interlock Stop Protection

Automatic Fire/ Pressure Regulation

Simple Operation

Automatic PLC ON/OFF

Visible Working Pressure

Visible Steam Temperature

Adjustable Working Pressure

Visible Exhaust-gas Temperature

Application

Disel fired steam boiler is being widely used in hospitals,

schools, textile mills, garment factories, large supermarket,

garment factories, dyeing factory, hotel, dining room, dining room,

swimming pool, food factory, beverage factory, soy products, meat

products factory, cannery, brewery, pharmaceutical factory, packing

plants, building materials factory, paint factory and other places

of the enterprises and institutions.

FAQ

1. What are the available fuel for the oil gas fired boiler?

Oil gas fired boiler could burn both liquid fuel and gaseous fuel.

The liquid fuel could be heavy oil, light oil, diesel, furnace oil,

bunker oil, LPG (liquefied petroleum gas), etc. The gaseous fuel

could be natural gas, city gas, bio-gas, etc.

2. Whether the boiler can burn dual fuel or multi-fuel?

boiler have oil burner, gas burner, and oil&gas dual fuel

burner, we can offer the specific burner based on customers’

requirement.

3. What is the thickness of combustion chamber?

the thickness of corrugated furnace is different based on working

pressure and furnace diameter, generally, the thickness is between

10~18mm, large combustion space, and combustion sufficient.

4. What is the inlet pressure of gas burner?

The inlet gas pressure is different for different capacity boiler,

for example, the pressure for 2 ton steam capacity boiler is about

8~10KPa, while for 4 ton steam capacity boiler is about 18~20KPa.

5.The brand of burner?

The brands of burner are Italy Baltur, Rellio, Elco, etc.